What is an HVLS Fan?

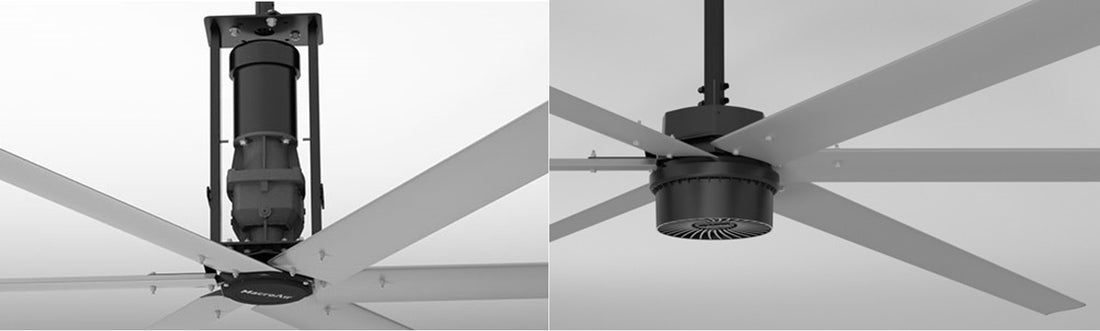

If you are in the market for a large diameter HVLS fan, you will face what can be a very confusing decision. For anyone scratching their head and asking, what the heck is an HVLS fan? - HVLS fans are defined as large diameter fans (usually ranging between 8 feet and 24 feet in diameter) that use their immense size to circulate air slowly and efficiently over a very large area. Some manufacturers claim air can be felt over as much as 20,000 sq.ft. from a single fan. While you may want to be careful with some of the numbers tossed around, we will save that discussion for another day. Generally speaking, HVLS fans made by the leading manufacturers move massive amounts of air that is almost unbelievable without seeing one for yourself. As you begin narrowing down your choices you will eventually find yourself trying to decide between drive systems that consist of either a gear motor (usually an AC induction motor paired with a gearbox to reduce the rpm to a specific ratio) or what is referred to as a direct drive motor (usually a permanent magnet, electrically commutated motor that does not require a gearbox to reach a specific rpm )

Direct Drive HVLS Fan or Gear Drive HVLS Fan?

This is the question people most commonly want answered when they are trying to make an HVLS fan purchase. Unfortunately, it's just not that simple. In answering this question, let's start by considering the combustion engine. There are numerous types of combustion engines used in a variety of ways. V configurations, flat heads, rotary, inline, short blocks, small blocks... the list goes on and on. So, does anyone know which of these combustion engines are the absolute best? No, because each engine is designed for different things and the only way to choose the best engine is to understand what we are trying to accomplish with the engine. Choosing between a direct drive fan and a gear motor fan is no different. To make the best choice we must define what we are wanting to accomplish. So before we jump into thinking about our needs, lets gain a better understanding of how these two platforms differ.

Pros and Cons - Direct Drive vs. Gear Motor

Direct Drive

Pros - Direct drive motors are compact, create instant torque and their speed can be controlled electronically (eliminating the need for rpm reduction through a gearbox). The lack of gears and fewer mechanical components makes this drive system very quiet in operation and significantly reduces mechanical failures. (In most cases there is almost no audible noise from the motor itself). Lastly, the compact nature of these motors affords the opportunity for aesthetically pleasing designs and custom color options.

Cons - These motors typically have high pole counts and may use expensive rare earth magnets in their construction. This usually leads to higher costs, ultimately meaning you will pay more. While these drive systems have fewer opportunities for mechanical failures (because there are no gears, oil, bearings, seals), they are much more sophisticated from an electronics perspective. So the gains one might recognize from fewer mechanical parts can sometimes be offset by the need for microprocessors and other sensitive electronics required to operate them.

Gear Motor

Pros - AC induction motors are simple in their design and very robust. When these motors are properly paired with a high quality gear reduction, they normally experience very few failures. This technology has been successfully used and perfected for decades, leading to lower costs and high quality which can be passed along to the customer. This type of motor system is typically paired with a variable frequency drive for speed control and other operations, which also has a long history of success in even the harshest of environments. The cost effectiveness + robust components + high output of this drive system makes it ideal for both harsh environments and non-conditioned spaces that need a lot of air movement.

Cons - While these drive systems are tremendously robust, they are not compact and they tend to be heavier than the direct drive equivalents. Also, since they use mechanical gears as a primary means of rpm reduction there is audible gear noise that is usually not audible in a manufacturing plant, but can be a nuisance in a quieter space like a restaurant. Lastly, the industrial nature of this drive system makes it difficult to design these fans with aesthetically appealing concepts.

Applying the Pros and Cons

Restaurants, Lobby Areas, Showrooms, Churches, Fitness Centers, Office Space

These type spaces will most likely require aesthetically pleasing design features, silent operation and are not considered harsh environments. They are also likely to be conditioned spaces so the output needs are much less. This allows for some cost savings, because higher output increases the costs associated with direct drive motors - Direct Drive is a very common selection for these types of spaces.

Manufacturing Plants, Distribution Centers, Warehouses, Stadiums, Aviation Hangars

These type spaces are most often not conditioned and can also be very harsh environments. Noise is not typically a concern because the ambient noise levels are often far greater than any gear motor. In these spaces, there is normally a great need for high airflow output to counter the non-conditioned environment. Lastly, aesthetic appearance is usually not a priority in these spaces. - Gear Motor is a very common selection for these types of spaces.

Given the information above, one might over simplify things by assuming direct drive is only used for commercial type spaces and gear motors are only used in industrial type space. Life is never that simple. There are many industrial type customers that choose direct drive fans and many commercial type customers that choose gear motor fans. These people didn't necessarily make a bad decision, they simply had different priorities in what they wanted to accomplish.

Here are some examples of how certain priorities can sway people in a different direction:

A fitness center with high ceilings and limited air conditioning - This is a commercial type application that may find the gear noise created by a gear motor acceptable because their greater concern is high airflow output to offset an undersized air conditioning system. If high airflow is the priority along with upfront cost savings, the equivalent direct drive fan (to move the same amount of air as a gear motor fan) is most likely not a justifiable additional expense.

Industrial buildings with high ceilings using direct drive fans. - It's not uncommon for industrial owners and managers to want the latest and greatest technology. They are willing to pay a premium for having a silent operating fan, with aesthetic appeal and no chance of mechanical failures. Direct drive fans with industrial level output are usually more expensive than the gear motor equivalent, but some people justify the additional expense because they want the newest technology and/or they receive a better factory warranty.

Google is Your Ally When Choosing An HVLS Fan

Do your research and stick to the leading manufacturers. This is not your typical $199 fan you pick up at the local DIY center. These are sophisticated pieces of equipment that require thoughtful application and professional installation. The top manufacturers in this business have been designing and manufacturing these fans for 20 years or more. There are many new brands and manufacturers entering the market, so make sure you know if you are working with a seasoned pro or just a new kid on the block. Happy Hunting!